Pipelines Manufacturing

Pipelines Manufacturing

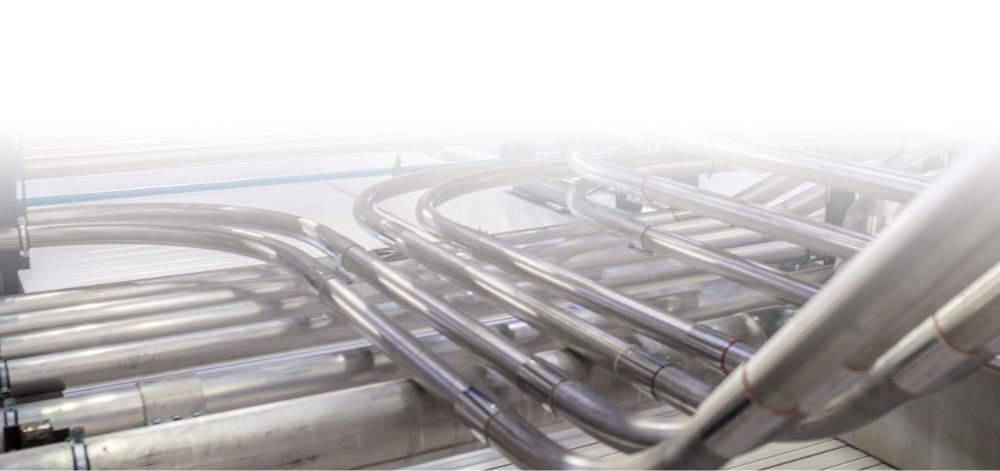

We produce industrial pipelines that transfer power between machines, perform the process, and ensure the circulation of the fluid in the facility.

After the efficiency analyzes made by considering the sector and process data, we provide the pipeline installations and commission the system by using the seamless, welded or hybrid piping solutions suitable for the project.

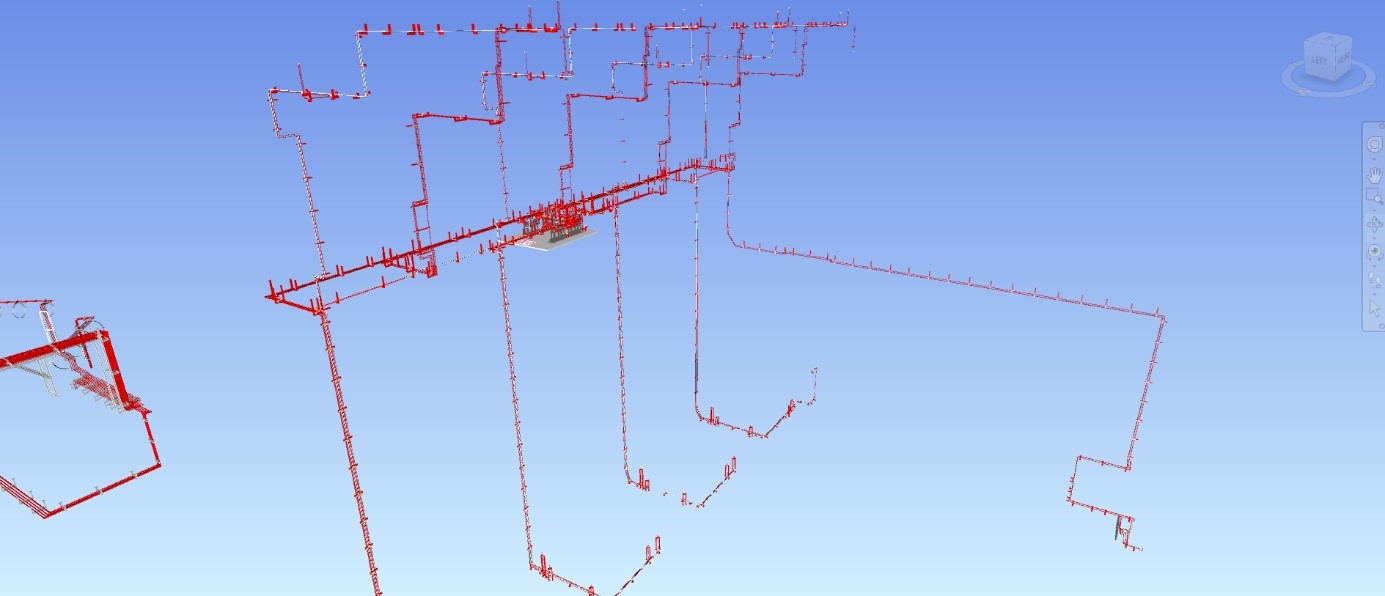

Before manufacturing, the installation is drawn and the material list is drawn up. With the installation drawings and simulations, the possibility of overlapping the pipes to be manufactured with different equipment, machines and lines is determined. This preliminary work minimizes the disruptions and error repetitions that may occur during manufacturing before starting the field work.

Pipeline installation mainly uses three types of pipe joining techniques. All of these methods can be used depending on the condition of the pipeline.

Walform: By using walform technology for pipes with an outer diameter of up to 42 mm, it prevents pipes of this diameter from being subjected to welding, and welding errors in these small diameters are prevented from adversely affecting the system. All pipes to be used in Walform technology; Cold drawn seamless phosphate coated EN 10305-4 E235+N (St. 37-4 NBK annealed) (heat treated and annealed) up to 42 mm in accordance with DIN 2391 C norm, both sides are covered.

Flare Flange: This method is similar to the walform method, but with a different method, it enables pipes over 42 mm to be joined without welding. With the weldless joining method, thermal stresses that will occur in the weld area, welding residues and inspections for welding control are eliminated.

Welded fabrication: This is the classical method and the quality of the weld is very important. Hot steel drawn seamless pipes are used in sizes larger than 42 mm in accordance with the DIN 2448 norm. The assembly of these pipes is done only by TIG welding and the delivery is carried out after the post-process NDT controls.